Product Description:

Working Principle

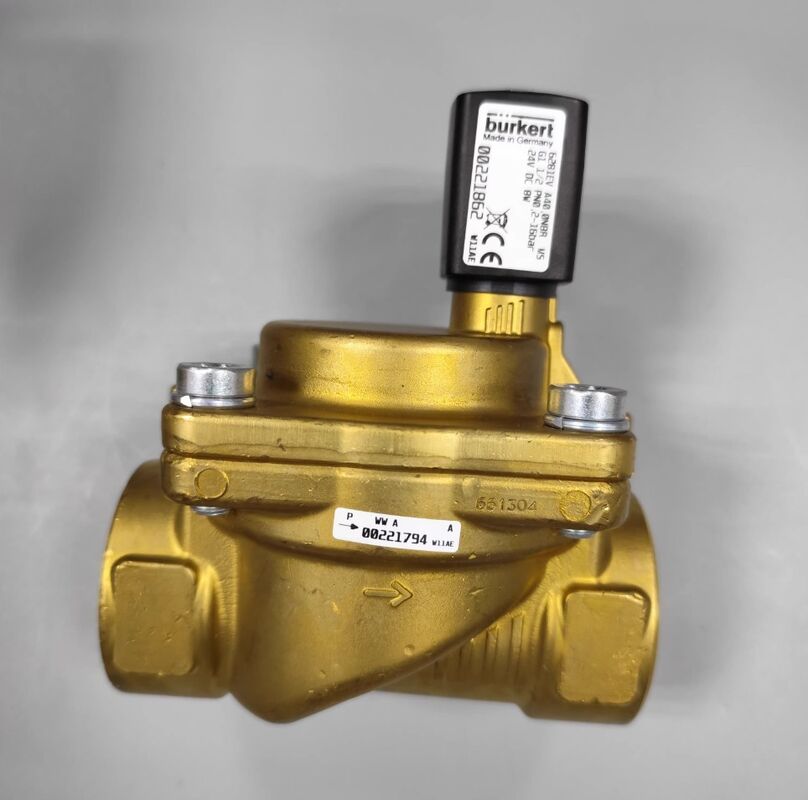

This valve features a servo-assisted design utilizing a pilot isolation diaphragm combined with plunger actuation. The pilot valve functions as a rotary armature or rocker solenoid valve equipped with an isolation diaphragm, ensuring that the medium does not pass through the pilot orifice. This design provides excellent resistance to clogging.

When opening, a minimum differential pressure of 0.2 bar is necessary to activate the main diaphragm. The pilot valve regulates the pressure within the main chamber to facilitate valve opening.

During closing, a damped mechanism guarantees a quiet and water-hammer-free shutoff, minimizing pipeline impact and reducing noise pollution.

For energy efficiency, an optional KD dual-coil technology is available, which automatically lowers power consumption after the initial actuation. This feature is ideal for applications requiring long-term continuous operation.

Core Advantages

The valve body is offered in both brass and stainless steel options, with sealing materials including NBR, EPDM, and FKM, making it compatible with water, gases, various chemicals, and capable of handling high-temperature conditions.

High reliability is ensured through the use of a centrally threaded coil with vibration resistance and epoxy resin encapsulation for chemical protection. Additionally, the pilot isolation diaphragm reduces the risk of clogging and leakage.

Flexible customization options include a manual override for commissioning and maintenance purposes, KD energy-saving coil, and explosion-proof certifications. These features make the valve suitable for challenging and hazardous environments.

The product complies with multiple standards such as drinking water regulations, ATEX explosion-proof requirements, and UL/CSA certifications, enabling its use across different regions with stringent regulatory demands.

Typical Applications

Common uses include municipal and industrial water treatment systems as well as drinking water supply systems, where standard brass models meet relevant standards.

The valve is also applicable in food and beverage industries and pharmaceutical liquid preparation systems, utilizing stainless steel bodies with EPDM or FKM seals to satisfy hygiene requirements.

It can serve in transfer systems for compressed air, hydraulic oil, and general chemicals, with material selection tailored to the specific properties of the medium.

Furthermore, fluid control in hazardous areas is supported with models certified under ATEX and IECEx standards.

Selection & Operation Notes

When selecting this valve, ensure the working differential pressure is equal to or greater than 0.2 bar to guarantee reliable opening.

Medium compatibility should guide material choice: stainless steel body with FKM seals is recommended for highly corrosive media, whereas standard brass bodies with EPDM seals are suitable for drinking water applications.

For optimized working conditions, consider KD dual-coil options to reduce energy consumption in continuous operation scenarios. Explosion-proof certified models must be specified when deploying in hazardous areas.

During installation and maintenance, it is advised to install a strainer upstream to prevent impurities from entering the valve. Avoid applying pipe stress on the valve body by independently supporting the pipeline. The manual override should only be used for commissioning and emergency situations, and must not be employed for prolonged forced openings.

Technical Parameters:

| Product Type |

6281 |

| Orifice |

DN 10…DN 50 |

| Orifice Size |

DN 10…DN 50 |

| Seal |

NBR |

| Temperature Range |

-10℃~100℃ |

| Application |

Fluid Control in Industrial Automation, Water Treatment, Chemical Processing |

Applications:

The Burkert Solenoid Control Valve, part of the renowned BURKERT brand, is an essential component widely used in various industrial automation applications. With its robust design and CE certification, this valve ensures reliable performance and safety across numerous fluid control scenarios. Designed to handle an orifice size ranging from DN 10 to DN 50, the Burkert Fluid Control Valve is versatile enough to meet diverse operational requirements, making it suitable for controlling the flow of liquids and gases in complex systems.

One of the primary application occasions for the Burkert Solenoid Control Valve is in industrial automation, where precise fluid control is critical. It is extensively used to regulate the flow of fluids in manufacturing processes, ensuring accurate control and automation of machinery. Its temperature range of -10℃ to 100℃ and the durable NBR seal make it ideal for environments that experience moderate temperature fluctuations and require leak-proof sealing for optimal performance.

Water treatment facilities also benefit greatly from the use of the Burkert Fluid Control Valve. Its reliable operation helps in the efficient management of water flow, filtration systems, and chemical dosing, which are vital for maintaining water quality and safety standards. The valve’s design supports the handling of various chemicals, making it a perfect fit for chemical processing plants where precise fluid regulation is paramount.

The Electric Solenoid Valve is also favored in chemical processing industries where it controls the flow of corrosive and non-corrosive fluids. Its quick response time and dependable sealing reduce downtime and maintenance costs, ensuring continuous and safe operations. The valve’s packaging options, including cartons or customized packing as per client requirements, guarantee protection during shipment and ease of handling upon delivery.

With a minimum order quantity of just one piece and a supply ability of 5000 pieces per month, BURKERT offers flexibility and scalability to meet different project sizes. Customers can negotiate pricing and benefit from diverse payment terms such as T/T, Western Union, and Paypal. Delivery is efficient, with products shipped within 1-7 working days after payment confirmation, making the Burkert Solenoid Control Valve an excellent choice for industries seeking dependable and timely fluid control solutions.

Packing and Shipping:

Burkert solenoid valves are carefully packaged to ensure maximum protection during transit. Each valve is securely placed in a custom-fitted box with protective padding to prevent any damage from shocks or vibrations. The packaging materials are selected to be durable and environmentally friendly, ensuring the product arrives in perfect condition.

For shipping, Burkert solenoid valves are dispatched through reliable carriers with tracking options available. The shipping process includes careful handling and timely delivery to meet customer requirements. International shipping is supported with all necessary customs documentation provided to facilitate smooth import and export procedures.

Customers are advised to inspect the package upon receipt and report any damage immediately to ensure prompt resolution. Proper storage and handling instructions are included within the packaging to maintain the integrity and performance of the solenoid valve.